1 / 2

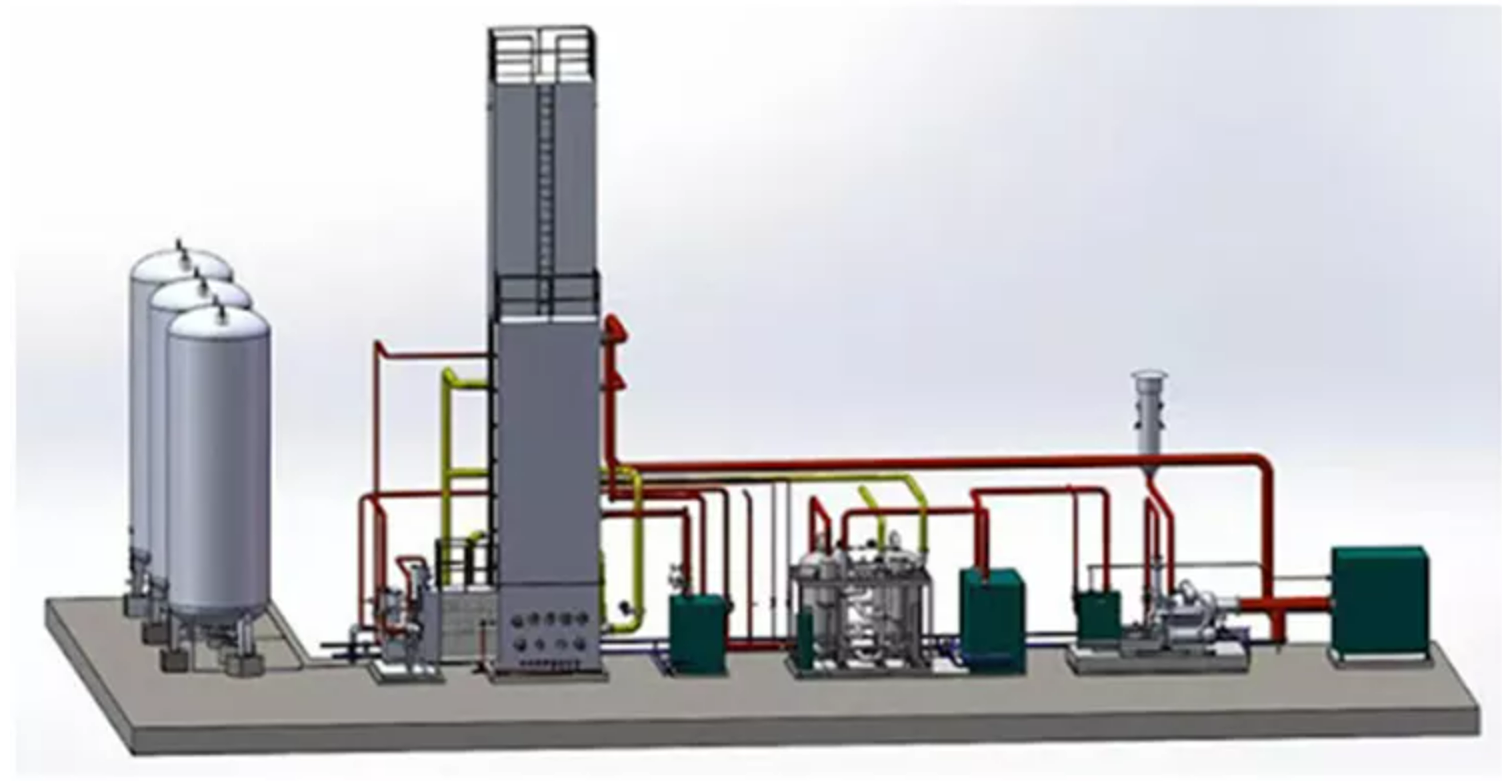

Kunpeng 산업 산소 식물 공기 분리 공장

최신 가격을 얻으십시오

문의를 보내십시오

| place of origin : | China |

|---|

더

Shenzhen KunPeng Precision Intelligent Technology Co., Ltd

당신은 또한 좋아할 것입니다

제품 설명

Kunpeng 공기 분리 장치 제조업체

주요 구성

1. 공기 압축기 : 공기는 5-7 bar (0.5-0.7mpa)의 저압에서 압축됩니다.

2. 사전 냉각 시스템 : 공기 온도를 약 12 ° C로 냉각시킵니다.

3. 정화기에 의한 공기 정화 : 쌍둥이 분자 체어기

4. Expander에 의한 공기의 극저온 냉각 : 터보 팽창기는 공기 온도를 -165 ~ 170 ℃ 미만으로 냉각시킨다.

5. 공기 분리 컬럼에 의한 액체 공기를 산소 및 질소로 분리

6. 액체 산소/질소는 액체 저장 탱크에 저장됩니다.

사양 분류

|

Product Name

|

Cryogenic Air Separation Unit

|

Oxygen Purity

|

≥99.6%

|

|

|

Production

|

50Nm³/h—5000Nm³/h

|

Nitrogen Purity

|

≥99.99%

|

|

|

Brand

|

KunPeng

|

Model

|

KDONAR

|

|

|

Main Part

|

Air compressor system, Pre-cooling System, Air Purification System, Fractionating Column System, Turbo Expander System, Filling System, Instrument and Electric Control System

|

|||

|

Application Field

|

Medical & Industrial & Animal husbandry & Defense

|

|||

프로세스 소개

|

No

|

MAIN PART

|

FUNCTION

|

||

|

1

|

Air Compression System

|

Air be compressed to 0.5-0.7 Mpa by air compressor, Imported centrifugal air compressor, high efficiency, low consumption, stable and reliable operation

|

||

|

2

|

Pre-cooling System

|

The air is pre-cooled to 5-10℃ in the pre-cooling unit, and the moisture is separated. The original imported screw refrigeration compressor and the air-conditioning unit combined with all imported refrigeration components are equipped with a water separator, manual and imported automatic drains to drain water regularly.

|

||

|

3

|

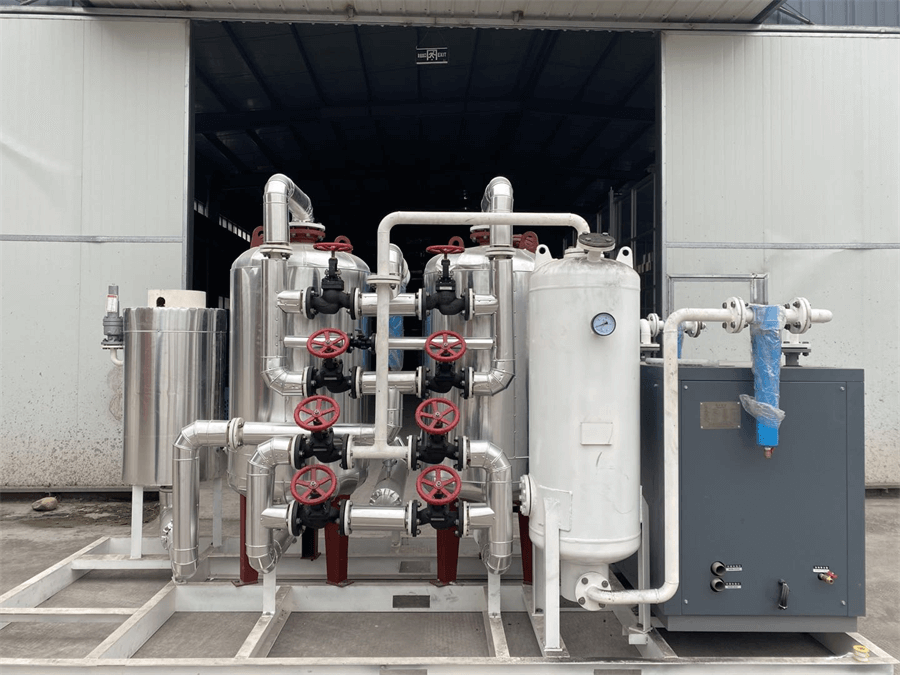

Air Purification System

|

Removing the remained moisture, carbon dioxide and hydrocarbons of compressed air in the molecular sieve purifier. The purifier adopts a vertical single-layer bed with simple and reliable structure and low resistance loss; built-in filter, blowing off and purifier regeneration at the same time; high-efficiency electric heater ensures complete regeneration of molecular sieve

|

||

|

4

|

Fractionating Column System (Cold Box)

|

The heating, cooling, liquid accumulation and purification of the fractionating tower can be completed in one way, and the operation is simple, quick and easy. Adopt aluminum plate-fin heat exchanger, aluminum convection sieve plate tower, the entire fractionating tower equipment pipeline adopts argon arc welding, the tower body and main pipeline in the cold box are made of high-strength aluminum alloy or stainless steel to increase the strength , Reduce the torsion damage of the pipeline. The equipment brackets, pipes and valve brackets in the cold box shall be made of stainless steel or aluminum alloy. The cold box is insulated with pearl sand and slag wool to ensure that the loss of cold capacity is minimized. The cold box structure guarantees the overall strength and the requirements of anti-seismic and wind resistance, and guarantees the load-bearing capacity of the cold box. When the cold box is running, it is equipped with airtight protection and safety devices. The main equipment in the cold box is equipped with electrostatic grounding. The cold valve and pipeline in the cold box all connections are welded, and flange connections are avoided.

|

||

|

5

|

Turbo Expander System

|

The air expands and cools in the turbo expander and provides the cooling capacity required by the device.The turbo expander adopts gas bearing, which is simple and reliable, easy to operate, and high efficiency. The cold box of the expander is set separately for easy maintenance.

|

||

|

6

|

Heat Exchange System

|

The air exchanges heat with the refluxing oxygen, nitrogen, and dirty nitrogen in the heat exchanger of the fractionation tower, and is cooled close to the liquefaction temperature, and the refluxed oxygen, nitrogen, and dirty nitrogen are repeatedly heat exchanged to the ambient temperature;

|

||

|

6

|

Filling System

|

Single gas production: Internal compression process ( Cryogenic liquid pump, High pressure vaporizer, Filling manifold).

Multi-gas production: External compression process (Oxygen & nitrogen & argon booster, Filling manifold).

|

||

|

7

|

Instrument and Electric Control System

|

Siemens imported brand, Fully automatic production system, Digital control system

|

||

|

8

|

Others

|

Equipment layout drawing (according to civil engineering design), Process pipe design drawings, Instrument electrical design drawings, etc.

|

||

극저온 공기 분리 공장은 널리 사용되며, 다른 응용 시나리오에는 흐름, 순도, 압력, 이슬점 및 기타 매개 변수에 대한 특정 요구 사항이 있습니다. 쇼핑 경험을 행복하게하려면 수요 정보를 남겨 주시면 전문 엔지니어가 연락하고 특정 기술 솔루션을 설계 할 수 있습니다. 가스 생산 장비에 상담하십시오.

이 공급 업체에 문의를 보내십시오

문의를 보내십시오